But the first settlement is different. The first settlement starts with nothing. In Earth orbit there is vacuum, a variety of environmental hazards, unrealized access to extraterrestrial resources, and solar energy. Nothing more. There is no scheduled transportation service, no port to put into for supplies or repairs, no grocery store, no refueling station, no building supply store, no dirt to grow food in, no water. Nothing.

We do offer an incentive for why it would be important to build the first settlement quickly. Whether or not one believes that global warming is a real threat, if conclusive evidence were provided that it would cause global extinction within a lifetime, then unlimited resources would become available to stop it. Studies have shown that a solar shield at the Earth – Sun L1 libration point (a point in space about 900,000 miles away where orbital mechanics enables a satellite to stay in place between the Earth and Sun) need only reduce sunlight by 0.5%, and the entire global warming threat goes away. The shield would have to be almost the size of Texas. The Space Settlement Design Competition scenarios are based on the premise that the first space settlement would be built as a construction base for such a solar shield. The urgency of saving the Earth would put a high priority on building that space settlement as quickly as possible. So, how do we propose that the very first space settlement–named Alexandriat in the Competition–could be built in only a dozen years? Even the optimistic NASA studies of the 1970’s predicted a 22-year construction schedule for the first settlement.

The simple answer is that construction happens quickly because it has to happen quickly; the situation for the Earth is urgent. The only question for the designers is HOW to get it operating quickly. We start with the assumption that Alexandriat doesn’t have to be beautiful or elegant or even durable enough to last longer than the construction process for the solar shield. It has to be functional, it has to be self-sufficient, it has to be comfortable enough that the people living there won’t go crazy, and it has to provide facilities for building the solar shield. Anything else is fluff.

We also add an assumption that the solar shield–with the space settlement required for its construction–is such a high priority for the world’s peoples that conventional practices of protecting company proprietary data and national technologies are set aside until the project is completed. As in World War II, innovative designs developed by one company are licensed to other companies and even other nations, in order to get the job done. No one company could fulfill a contract to complete this project. Even with unlimited budget, there are not enough qualified engineers and technicians in any one nation who could be made available to complete this project quickly. The effort must be inter-company and multi-national. Money may be no object, but the number of available engineers and technicians limits how fast it can be spent.

The Foundation Society initiates the project by assembling a team of top managers and engineers from established aerospace companies. The stakes are high, so virtually anybody who is needed can be excused from current duties. The core team is relatively small, to enable quick decision-making; perhaps five executive managers, ten technical managers, and 100 engineers. Before beginning the design process, this team establishes design requirements and guidelines that make the settlement easier to build. Artificial gravity of 0.5 g and a 10 psi atmosphere are entirely adequate for human existence, but these reductions from Earth surface conditions reduce the stresses in the structure so that construction is more feasible. To save design time, the basic torus shape described in the 1970’s studies can be defined as the baseline. The details, however, are completely new–different materials, different construction techniques, modifications to accomplish the solar shield construction project, updated interior features.

Simultaneously, a Human Resources team arranges for the employees who will work on the project. The most challenging aspect of building a huge project quickly is hiring and coordinating the tens or hundreds of thousands of people needed to make it happen. With nearly full employment of technical people in the United States, Canada, Western Europe, Australia, and Japan, the necessary employees must be found elsewhere. The companies of these nations are contracted to do more of what they do well–in support of the project, they build and operate more assets that it is known will be needed: launch vehicles, rocket engines, special-purpose satellites, space tugs (modified for long-distance cargo deliveries), and space stations. They conduct the research to develop new materials, control systems, robots, and improved manufacturing methods. Although no crewed lunar landing craft has been built since the early 1970’s, corporations open up their vaults of proprietary designs and reveal that valid conceptual designs exist to augment Constellation program vehicles; they were just waiting for somebody to pay for development. Construction of all aspects of needed transportation infrastructure is underway within seven months.

The vast majority of effort on the settlement and solar shield, however, is the “grunt work” of detailed designing, analyzing, testing, building, transportation planning, and assembly scheduling of the required components. For these tasks, the Foundation Society taps into vast reserves of underemployed but well-trained and highly skilled individuals in Russia, Eastern Europe, India, Pakistan, China, Brazil, and several other countries not typically considered at the forefront of innovative space technology development. Specialized training is provided as required, sometimes in cooperation with universities. Coordinating all of these efforts worldwide is a huge task. The core team compartmentalizes the requirements into portions that can be accomplished by the various teams world-wide. They very specifically define the interfaces between the pieces that are designed by the different teams. They travel extensively to assure that each team has the information it needs, and is on schedule and producing its own products as expected. As each team finishes a part of the project, another part is assigned. Early tasks define details that enable construction to begin on the overall shell of the structure and the solar shield manufacturing facility. The designers proceed into deeper and deeper details–for example, electrical power distribution, sewage processing, farming techniques; then street maps, municipal buildings, and parks; finally the details inside individual businesses and residences.

Quick construction of the space settlement requires development of new techniques and unconventional methods. Transportation from Earth’s surface to space is a bottleneck, so utilization of non-terrestrial resources speeds the process. Some of the tools proposed in the old NASA 1970’s studies are “dusted off” and improved, most notably the electromagnetic mass driver concept for efficiently launching materials off the moon. Refining vast quantities of materials in space requires time to develop zero-g refining processes and build the refineries, so use of materials in their natural state also speeds the process. The ideal situation would be to build the settlement from dirt. And, as much as possible, that’s how it’s done.

Dirt has been proven, by several methods, to be a fine construction material for structures in compression–arches and domes that are designed to keep their shape against the pull of gravity. Acceptable structures for a mining camp on the lunar surface can be built in a matter of days, and the construction technique is simple enough that it can be automated with robots. “Superadobe” construction is accomplished by compacting dirt–any kind of dirt–into long tubes of flexible material. Rugged fabric that can handle the space environment was developed for the Mars Pathfinder mission in the mid-1990’s, and with some minor adjustments to the manufacturing process, miles of lightweight superadobe tubing are available as soon as the necessary vehicles can ship it to the lunar surface. Robots are programmed to fill the tubing and stack it, layer upon layer, to form domes for buildings; the process is much like stuffing sausage casings. Each layer of superadobe is about six inches high and two feet thick. After the domes are formed, some additional shielding is provided by piling loose dirt on top of them, and they are sealed to be airtight with a glaze on the interiors. The additional dirt also provides insulation to protect the interiors from the extremes of lunar temperatures.

After the lunar base buildings are completed, the robots continue to pack superadobe tubes. When the mass driver is completed, it is immediately employed in the business of launching superadobe. The technology of electromagnetic levitation that makes the mass driver work had not been implemented on a commercial scale when the 1970’s NASA studies were conducted; now, essentially all that is required to build a lunar mass driver is to deliver components of the tracks on which high-speed trains operate, and to modify and adjust the power and control systems for this new application. As proposed in the 1970’s NASA studies, the mass driver only sends material to a collection point in space, from which it is transported to the space settlement construction site. One of the design teams conducts a “trade study” to optimize the size of each mass-driven package and the frequency at which packages are sent; another team identifies an easy way to bind each superadobe package so it will stay intact through the launch process (the 1970’s study proposed launching 40-lb packages at the rate of one or two per second; larger packages are preferred to enable longer lengths of superadobe to be sent in each package). The mass driver requires a lot of power; continuous solar power is acquired on the moon by building at one of the poles.

In order for superadobe to be useful as a construction material for the space settlement, however, a means must be found for keeping it stable in tension–the settlement’s rotation puts forces into the outside surface of the structure that act to pull it apart. Some of this force can be reacted by using a superadobe tubing material that is exceedingly strong in tension. Only the outside surface needs this capability, however, so it is not necessary to go to the expense of making all of the tubing from more exotic materials. It is sufficient to build a mesh or net of high-strength fibers–perhaps similar in appearance to chicken wire–to encase the outer surface of superadobe. More stability is acquired by weaving the superadobe to form the torus; the relatively short lengths that can be launched by the lunar mass driver are as strong as continuous superadobe coils when they are woven. The necessary wall thickness for radiation shielding is acquired by weaving multiple layers of superadobe.

Also adopted from the 1970’s studies is the location for the first settlement, an orbit around the Earth-Moon L5 libration point. It’s closer and easier to get to than the solar shield construction location, and there are advantages for future infrastructure development. Only the materials for the solar shield, with a minimal construction crew, need to go all the way to the Sun-Earth L1 libration point for solar shield assembly.

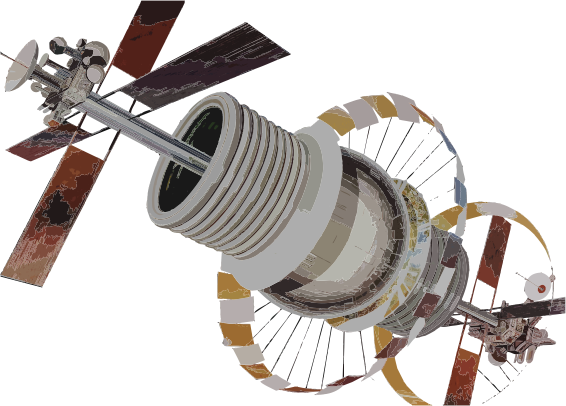

The construction process for the settlement starts with minimal materials. A small spherical hub is built as a “construction shack” for the engineers and technicians who are responsible for assembly of the settlement. They attach thick kevlar ropes (coated to prevent deterioration by the sun) to the outside of the hub. The first narrow woven strip of superadobe (reinforced to withstand tension) is over three miles long. Its ends are joined in a hoop and the ropes from the hub are attached at regular intervals. When small ion engines spin the hub, the ropes tighten, and a spindly mile-wide “wagon wheel” takes shape. From that point, the spokes and rim are built up to their final dimensions as more material arrives and can be added. Living quarters on the rim are added, sealed, made habitable, and populated in small sections, so that at various stages of construction the structure resembles a large necklace of chunky blocks. After several hundred residents arrive, the solar shield manufacturing area is added to the hub, so that Alexandriat’s primary function can be fulfilled as quickly as possible. Construction is automated as much as possible, with robots programmed to assemble sections of superadobe into the torus sections and seal them in preparation for use.

Some other materials required in large quantities are also acquired from the moon. They do, however, require refining of the native materials, and ores are harvested from various lunar sites to acquire the desired elements. Oxygen, silicon, titanium, aluminum, iron, magnesium, calcium, and sodium are present in significant quantities on the moon, all bound up in oxides. Separating the components can be a difficult business, especially when rare (on the moon) catalysts like carbon are required for conventional processes. The elements are there, however, and unleashing thousands of creative chemists world-wide inspires some breakthrough separation and refining technologies. Silicon is made into solar cells; sodium makes a fine reflective coating for reflector mirrors; composites, glass, and ceramics are made from several of these materials; and each of the metals is used in appropriate applications. Composites and ceramics are easier to make from lunar materials than metals, and are used for most interior applications–walls of housing units and other buildings, furniture, plumbing and fixtures, bodies and chassis of vehicles for interior use, paving for streets and walkways, doors, cabinets, housings for computers and other equipment, robot bodies, and components of common appliances. As many products as possible are made from lunar materials to reduce the imports required to be launched from Earth. Some of the most mundane materials cause the greatest challenges, and dozens of teams work simultaneously until a solution is found for each–processes are developed to make cloth, string, paper, inks and dyes, flexible tubing and insulation, bicycle tires, paint, coatings for various uses, adhesives, cleaning agents, and other products either exclusively or primarily from lunar materials. With the exception of station-keeping motors and computerized control systems, the entire solar shield is constructed of lunar materials. The importance of the assignments brings out the utmost creativity in every person working on them, and miracles occur.

The most difficult substances to acquire from the moon are ironically the ones that are most common on Earth, air and water. At first, there is no choice; huge quantities of air and water are transported from Earth. Recycling and reclamation are refined to an art form; any losses must be made up with very expensive and time-consuming shipments. Ultimately, technologies are developed to divert small comets and asteroids to augment lunar resources.

With the introduction of microbes, lunar soil provides suitable growing media for agriculture. The early diet of Alexandriat’s residents is carefully planned to yield the most nutrition possible for the least amount of land area, resources, growing time, and risk of crop failure. Yield per acre is increased by use of hydroponics for many crops. Quick growing times for vegetables, squash, and some berries causes these foods to be much more common in the early diet than grain-based breads and pastas. Recipes adapted from primitive subsistence cultures provide good food that can be grown with less expenditure of resources. Rabbits and chickens augment lentils and beans as a source of protein. With time, a greater variety of foods is produced in the settlement, but highly processed foods like most breakfast cereals and salted snacks require manufacturing resources that the settlement can ill afford to expend on alternative flavors and textures of calories. A few tins of Pringles tucked into the precious weight allowance of a passenger from Earth are cause for a party at Alexandriat.

With commitment, cooperation, virtually unlimited budget, and a lot of luck, it can all come together in a mere dozen years. Humans have done it before and have legends to prove it: the P-51 Mustang went from concept to production in just months during World War II, one of Henry Kaiser’s companies built an entire ship in one day, the Apollo project went from a Presidential speech to a lunar landing in less than a decade, the Trans-Alaska Pipeline went from idea to completion in 12 years (only three years of actual construction). And the most amazing thing happens when these miracles occur: people accept them as normal events. Some of the technology stretches that build Alexandriat are adopted to improve processes on Earth. The influx of income into Third World countries raises the level of prosperity as economies are jump-started. Teams of engineers that cause miracles to occur for Alexandriat turn their attention to miracles that need to be performed at home. Perhaps more importantly, great human achievements inspire people to realize that they really can create miracles. When that happens, anything is possible.